Choosing the right transformer manufacturer isn’t just a matter of price. It’s a long-term strategic decision that impacts grid reliability, maintenance costs, procurement cycles, and public trust. From investor-owned utilities (IOUs), cooperatives, municipalities, and large-scale utilities, transformers are a foundational asset in the power distribution system. Poor transformer quality can mean costly outages, poor supply chain support, and non-compliance with modern grid reliability standards. However, the right partner can mean decades of reliable performance and peace of mind. Here’s a detailed buyer’s checklist for selecting a transformer manufacturer that meets today’s utility demands, courtesy of CMI.

1. Confirm Compliance with Industry Standards

Your vendor should design and test all transformers in full accordance with IEEE, DOE, ANSI, and NEMA guidelines. This ensures safety, efficiency, and interoperability across grid systems. Ask specifically if the manufacturer complies with the latest DOE 2025 transformer efficiency standards, and that they are ISO 9001/14001 certified. These certifications aren’t nice-to-have; they’re mandatory for long-term reliability and grid compatibility.

2. Look for North American-Based Manufacturing

Transformer manufacturers with domestic production capabilities offer key advantages: compliance with Buy America Act procurement, faster lead times, and stronger supply chain control. U.S.-based operations also help you meet government funding requirements tied to American-made infrastructure. CMI manufactures all of its padmount and overhead distribution transformers in Arkansas and Florida, giving utilities and distributors confidence in quality, consistency, and availability.

3. Choose a Partner with Stainless Steel Tank Options

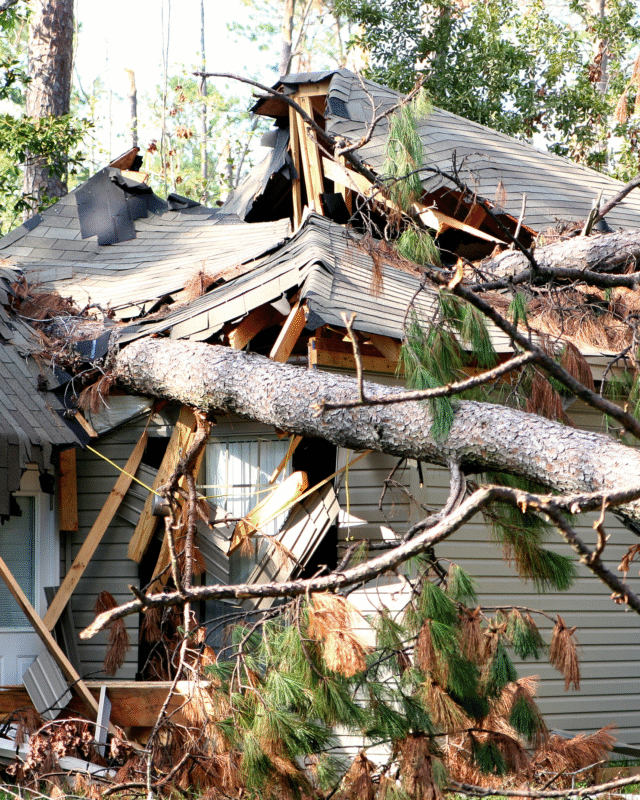

If your transformers are deployed in coastal, industrial, or high-humidity environments, stainless steel transformer enclosures can dramatically improve product longevity. Painted mild steel tanks corrode over time, increasing failure risk and total cost of ownership. CMI offers 304 and 409 stainless steel tank options that resist rust, salt spray, and chemical exposure. These corrosion-resistant transformers are ideal for utilities operating in flood-prone or hurricane-exposed regions.

4. Prioritize Customization Capabilities

Grid needs vary, and so should your transformer design. Your manufacturer should offer transformer customization across KVA ratings, voltage configurations, winding materials, insulation systems, and oil types. Ask about special features like smart sensor integration, tamper-proof cabinets, low-profile padmounts, and top/bottom bushing configurations. CMI works closely with utility engineers and distributors to deliver fully customized padmount and overhead transformers, ensuring performance alignment with every spec.

5. Demand Lifecycle Support and Documentation

Does your manufacturer offer post-installation support? Can they provide full technical drawings, serial tracking, and parts availability years after deployment? Look for a transformer partner that supports the full lifecycle of your equipment, not just delivery. Ask about maintenance guidance, field performance resources, and tech support availability. Lifecycle visibility reduces downtime and makes long-term asset management easier and more efficient.

6. Evaluate Production Capacity and Lead Time Reliability

Transformer procurement is high-stakes and time-sensitive. You need a manufacturer with scalable capacity and a reliable delivery record. Ask about lead time averages, raw material sourcing, and how they handle spikes in demand. CMI ensures dependable turnaround – even when global supply chains tighten. Consistent production and transparent scheduling give you predictability when it matters most.

7. Ask for Field-Proven Results in Challenging Environments

It’s one thing to build transformers. It’s another to build transformers that perform in real-world stress conditions. Look for case studies showing successful deployments in flood zones, heat-stressed regions, or salt-heavy coastal environments. CMI’s transformers are trusted by IOUs and co-ops in Florida, the Gulf Coast, and across the Midwest, where resilience and long life are mission-critical.

9. Confirm Their Commitment to Innovation and Quality

Transformer manufacturers should demonstrate ongoing investment in engineering, product development, and quality control. Are they developing new solutions or reliability technologies? CMI maintains an aggressive quality program, invests in American workforce development, and collaborates with top-tier utility engineers to enhance transformer performance and develop components that raise the bar across the industry.

10. Choose a Long-Term Partner, Not Just a Vendor

Ultimately, your transformer supplier should operate as a strategic partner – one that understands your region, your grid goals, and your expectations for performance and reliability. Look for evidence of integrity, customer satisfaction, and long-term collaboration. From spec development to post-deployment support, CMI delivers responsive service, high-quality product builds, and a customer-first approach that has made us a trusted name in utility-grade transformers for nearly 80 years.

In conclusion, selecting the right transformer manufacturer is about more than spec sheets. It’s about partnering with a company that can deliver quality, customization, and compliance at scale. If you’re sourcing distribution transformers for storm-prone areas, regulatory compliance, or high-performance networks, CMI offers stainless steel solutions, U.S.-made reliability, and customized engineering to meet your transformer demands.